Page 304 - DC

P. 304

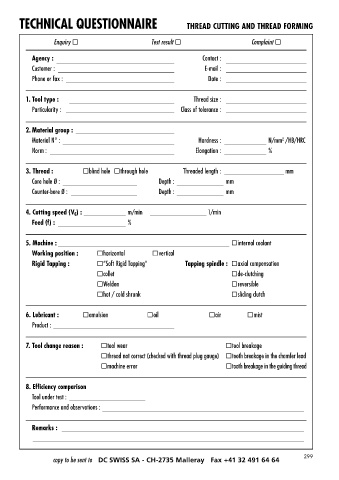

TECHNICAL QUESTIONNAIRE THREAD CUTTING AND THREAD FORMING

Enquiry Test result Complaint

Agency : Contact :

Customer : E-mail :

Phone or fax : Date :

1. Tool type : Thread size :

Particularity : Class of tolerance :

2. Material group :

Material N° : Hardness : N/mm /HB/HRC

2

Norm : Elongation : %

3. Thread : blind hole through hole Threaded length : mm

Core hole Ø : Depth : mm

Counter-bore Ø : Depth : mm

4. Cutting speed (V ) : m/min 1/min

c

Feed (f) : %

5. Machine : internal coolant

Working position : horizontal vertical

Rigid Tapping : “Soft Rigid Tapping“ Tapping spindle : axial compensation

collet de-clutching

Weldon reversible

hot / cold shrunk sliding clutch

6. Lubricant : emulsion oil air mist

Product :

7. Tool change reason : tool wear tool breakage

thread not correct (checked with thread plug gauge) tooth breakage in the chamfer lead

machine error tooth breakage in the guiding thread

8. Efficiency comparison

Tool under test :

Performance and observations :

Remarks :

copy to be sent to DC SWISS SA - CH-2735 Malleray Fax +41 32 491 64 64 299