Page 293 - yt

P. 293

293

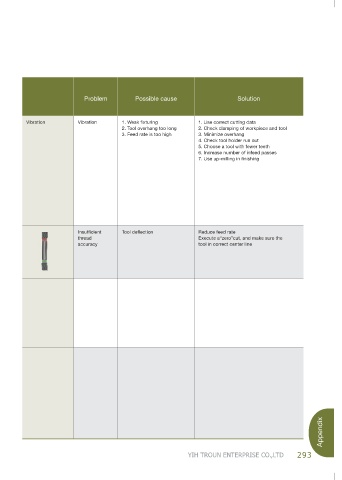

Solution 2. Check clamping of workpiece and tool Execute a“zero”cut, and make sure the

1. Use correct cutting data 3. Minimize overhang 4. Check tool holder run out 5. Choose a tool with fewer teeth 6. Increase number of infeed passes 7. Use up-milling in fi nishing Reduce feed rate tool in correct center line YIH TROUN ENTERPRISE CO.,LTD

Possible cause 1. Weak fi xturing 2. Tool overhang too long 3. Feed rate is too high Tool defl ection

Problem Vibration Insuffi cient thread accuracy

Vibration

1. Reduce cutting speed/use coated insert 2. Increase feed rate 3. Increase coolant fl ow rate 1. Reduce feed rate or Increas RPM 2. Use the tangential arc method 3. Check stability, minimize tool overhang 4. Increase number of infeed passes 5. Use a full-profi le insert tolerance 1. Use a coated carbide grade 2. Use correct cutting data 3. Use oil mist or cutting sluid 1. Increase feed,fz 2. Reduce s

Solution 6. Check toolholder run-out or insert mounting

Possible cause 1. Cutting speed too high 2. Feed,fz too low, 3. chip is too thin 4. Insuffi cient coolant 1. Chip is too thick 2. Vibration 1. Unsuitable carbide grade 2. Cutting zone temperature is too low 3. Very sticky material, such as low-carbon steel, stain less ste-els, and aluminum 1. Vibration 2. Re-cutting of chips 3. Burr formation on component 4. Poor surface fi nish 5.

Troubleshooting Problem Flank wear Chipping of cutting edge Material build up on the cutting edge Excessive wear causing short tool life YIH TROUN ENTERPRISE CO.,LTD

Excessive wear

causing short

tool life

292