Page 238 - yt

P. 238

4 In 1 Counter Bore Program Description

CNC No.G83(G98)

Peck drilling (CNC No.G83)

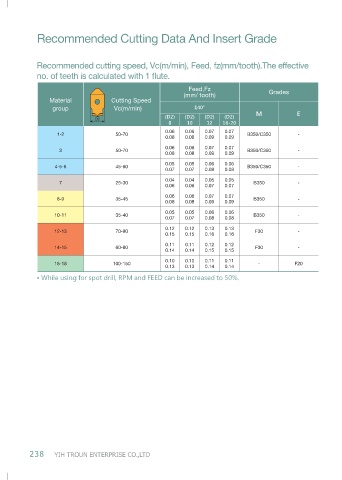

Recommended cutting speed, Vc(m/min), Feed, fz(mm/tooth).The effective

- Starting Point - Point - 1 - - - Point - - CNC No.G83(G99) F20 Counterbore Point 1 Point • The G83 cycle or peck drilling is for deep drilling or milling with chip breaking. The retracts in this cycle clear the hole of chips and cut off any long stringers (which are common when drilling in aluminum). This cycle takes a Q number which represents a "delta" increment along the

Grades E

Recommended Cutting Data And Insert Grade

B350/C350 B350/C350 B350/C350 B350 B350 B350 F30 F30 -

(D2) M 16-20 0.07 0.09 0.07 0.09 0.06 0.08 0.05 0.07 0.07 0.09 0.06 0.08 0.13 0.16 0.12 0.15 0.11 0.14

Feed,Fz (mm/ tooth) 140° (D2) (D2) 12 10 0.07 0.06 0.09 0.08 0.07 0.06 0.09 0.08 0.06 0.05 0.08 0.07 0.05 0.04 0.07 0.06 0.07 0.06 0.09 0.08 0.06 0.05 0.08 0.07 0.13 0.12 0.16 0.15 0.12 0.11 0.15 0.14 0.11 0.10 0.14 0.13

ute. (D2) 8 0.06 0.08 0.06 0.08 0.05 0.07 0.04 0.06 0.06 0.08 0.05 0.07 0.12 0.15 0.11 0.14 0.10 0.13 • While using for spot drill, RPM and FEED can be increased to 50%.

no. of teeth is calculated with 1 fl Cutting Speed Material Vc(m/min) group 50-70 1-2 50-70 3 45-60 4-5-6 25-30 7 35-45 8-9 35-40 10-11 70-90 12-13 60-80 14-15 100-150 16-18 238 YIH TROUN ENTERPRISE CO.,LTD