Page 211 - yt

P. 211

Center Drill

Spot Drill

211 211

F20

E - - - - - - - - Key L013 L013 L015 L02

Grades A B

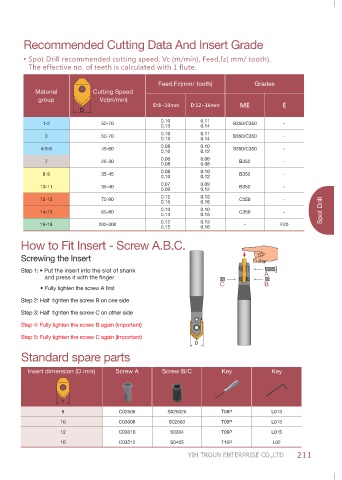

• Spot Drill recommended cutting speed, Vc (m/min), Feed,fz( mm/ tooth).

Recommended Cutting Data And Insert Grade

ME B350/C350 B350/C350 B350/C350 B350 B350 B350 C350 C350 - YIH TROUN ENTERPRISE CO.,LTD YIH TROUN ENTERPRISE CO.,LTD

Key T08P T09P T09P T10P

C

D:12~16mm

Feed,Fz(mm/ tooth) D:8~10mm 0.10 0.13 0.10 0.13 0.08 0.10 0.06 0.08 0.08 0.10 0.07 0.09 0.12 0.15 0.10 0.14 0.12 0.15 D Screw B/C S025025 S02503 S0304 S0405

0.12

0.12

0.09

0.10

0.08

0.06

0.15

0.13

0.16

0.13

0.16

0.10

0.14

0.10

0.11

0.11

0.14

0.12

The effective no. of teeth is calculated with 1 flute.

Cutting Speed Vc(m/min) D 50-70 50-70 45-60 25-30 35-45 35-40 70-90 60-80 200-300 How to Fit Insert - Screw A.B.C. Step 1: • Put the insert into the slot of shank and press it with the finger • Fully tighten the screw A fi rst Step 3: Half tighten the screw C on other side Step 4: Fully tighten the screw B again (Important) Step 5: Fully tighten the screw C again (Important) Screw A

Material group 1-2 3 4-5-6 7 8-9 10-11 12-13 14-15 16-18 Screwing the Insert Step 2: Half tighten the screw B on one side Standard spare parts Insert dimension (D mm) 8 10 12 16

angle 90° ME angle 90° 142° ME

Dimensions in mm AE L 2.0 4 2.5 5 3.0 6 3.0 8 E Inserts 10 PCS / Box M AE M4 x 0.7 2.0 M5 x 0.8 2.5 M6 x 1.0 3.0 M8 x 1.25 3.0 M10 x 1.5 3.0 Inserts 10 PCS / Box

D d 0.7 8 0.8 10 0.9 12 1.0 16 Uncoated CE K10 Dimensions in mm L1 D2 1.02 4.2 1.25 5.25 1.55 6.3 1.97 8.4 2.46 10.5 Uncoated CE K10 Steel/Cast Iron

Metal cermet CE60 D1 L 3.3 2.8 4.2 3.5 5.0 4.2 6.8 5.6 8.5 5.1 Metal cermet CE60

Grades CE25 F30 D 8 10 12 16 16 Grades CE25 F30 Aluminum

Chamfering application B350 C125

Carbide F20 C350 Carbide F20 C350 Cast Iron

90° 90° 142°

B350

C125

Part No . Spot application Part No . Steel/Stainless Steel • Please specify model number and grade of insert, ie.: A23-0802-M4-ME, B350

AE AEjÔ 0.01~0.02 23-0802-90-E 23-1002-90-E 23-1203-90-E 23-1603-90-E 23-0802-90-ME 23-1002-90-ME 23-1203-90-ME 23-1603-90-ME L1 AE AEjÔ 0.01~0.02 A23-0802-M4-ME A23-1002-M5-ME A23-1203-M6-ME A23-1603-M8-ME A23-1603-M10-ME Stainless Steel • Correct price and stock are based on current situation YIH TROUN ENTERPRISE CO.,LTD YIH TROUN ENTERPRISE CO.,LTD

23 Insert L d 90 D Tolerances (mm) DjÔ0.05~0.08 Inserts A23 Insert 90 L 142 D1 D2 D Tolerances (mm) DjÔ0.05~0.08 Inserts Steel • Steel/Stainless Steel/Cast Iron 210 210