Page 15 - yt

P. 15

15

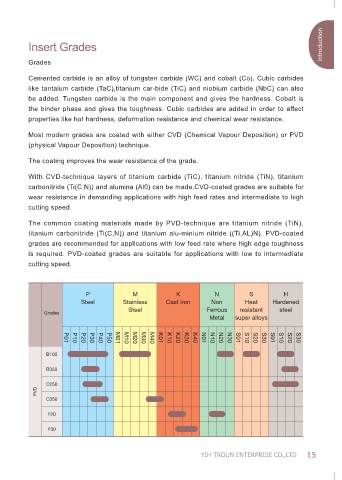

carbonitride (Ti(C,N)) and alumina (Al0) can be made.CVD-coated grades are suitable for

wear resistance in demanding applications with high feed rates and intermediate to high

Most modern grades are coated with either CVD (Chemical Vapour Deposition) or PVD

With CVD-technique layers of titanium carbide (TiC), titanium nitride (TiN), titanium

grades are recommended for applications with low feed rate where high edge toughness

is required. PVD-coated grades are suitable for applications with low to intermediate

The common coating materials made by PVD-technique are titanium nitride (TiN),

titanium carbonitride (Ti(C,N)) and titanium alu-minium nitride ((Ti,AL)N). PVD-coated

be added. Tungsten carbide is the main component and gives the hardness. Cobalt is

like tantalum carbide (TaC),titanium car-bide (TiC) and niobium carbide (NbC) can also

Cemented carbide is an alloy of tungsten carbide (WC) and cobalt (Co). Cubic carbides

the binder phase and gives the toughness. Cubic carbides are added in order to affect

S20

H Hardened steel S30

S10

properties like hot hardness, deformation resistance and chemical wear resistance.

S01

S20

S Heat resistant super alloys S30 YIH TROUN ENTERPRISE CO.,LTD

S10

S01

N30

N Non Ferrous Metal N20

N10

N01

K40

The coating improves the wear resistance of the grade.

Cast iron K10

K K30

K20

K01

M40

Stainless

M30

Steel

M

M20

M10

M01

P50

Insert Grades Grades (physical Vapour Deposition) technique. cutting speed. cutting speed. P Steel Grades P40 B100 B350 C250 PVD C350 F20 F30

P30

P20

P10

P01

8. Cutting edge designation Not mandatory information 9. Direction of cutting Right-rotated Left-rotated Neutral (R-and L-rotated) 10. Internal designation Machining conditions E = Easy M = Medium D = Diffi cult 11. For TAP only Tolerance : 6H、8H

F=25 f G=30 f N= 0 f P=11 f

04=4,76 mm 05=5,56 mm 06=6,35 mm 07=7,94 mm 08=8,00 mm 09=9,52 mm A=45 f D=60 f E=75 f F=85 f P=90 f Z=Special A=3 f B=5 f C=7 f D=15 f E=20 f Z=Special M0*= round inserts 00= sharp 01= 0,1mm 02= 0,2mm 04= 0,4mm 08= 0,8mm 12= 1,2mm etc *Metric version

6. Thickness 01=1,59 mm T1=1,98 mm 02=2,38 mm 03=3,18 mm T3=3,97 mm 7. Thickness 1nd letter 2nd letter nose radius

Inserts Code Keys X=Special 5. Cutting edge length YIH TROUN ENTERPRISE CO.,LTD

4. Type

14