Page 89 - logic

P. 89

MATERIAL GROUPS MULTI-MASTER

Engineered for

MAXIMUM

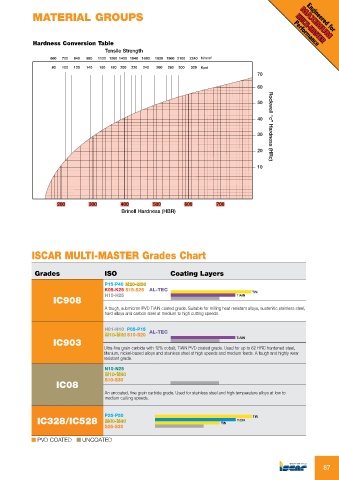

Hardness Conversion Table Performance

Tensile Strength

560 700 840 980 1120 1260 1400 1540 1680 1820 1960 2100 2240 N/mm 2

80 100 120 140 160 180 200 220 240 260 280 300 320 Kpsi

70

60

50

40

30 Rockwell “c” Hardness (HRc)

20

10

200 300 400 500 600 700

Brinell Hardness (HBR)

ISCAR MULTI-MASTER Grades Chart

Grades ISO Coating Layers

P15-P40 M20-M30

K05-K25 S15-S25 AL-TEC TiN

IC908 H10-H25 TIAIN

A tough, submicron PVD TiAlN coated grade. Suitable for milling heat resistant alloys, austenitic stainless steel,

hard alloys and carbon steel at medium to high cutting speeds.

H01-H10 P05-P15 AL-TEC

M10-M20 S10-S20 TiAIN

IC903

Ultra-fine grain carbide with 12% cobalt, TiAlN PVD coated grade. Used for up to 62 HRC hardened steel,

titanium, nickel-based alloys and stainless steel at high speeds and medium feeds. A tough and highly wear

resistant grade.

N10-N25

M10-M30

IC08 S10-S30

An uncoated, fine grain carbide grade. Used for stainless steel and high temperature alloys at low to

medium cutting speeds.

P25-P50 TiN

IC328/IC528 M30-M40 TiN TiCN

S25-S30

PVD COATED UNCOATED

87