Page 92 - logic

P. 92

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

RE APMX THSZMS

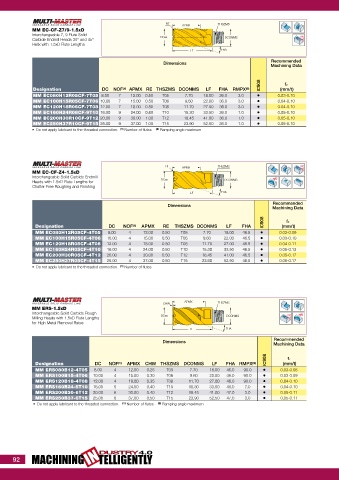

MM EC-CF-Z7/9-1.5xD

Interchangeable 7, 9 Flute Solid DCONMS Rd°

Carbide Endmill Heads 30° and 45° DCe8

Helix with 1.5xD Flute Lengths

LF FHA

Recommended

Dimensions

Machining Data

IC908 fz

Designation DC NOF (1) APMX RE THSZMS DCONMS LF FHA RMPX (2) (mm/t)

MM EC080H12R05CF-7T05 8.00 7 12.00 0.50 T05 7.70 18.00 36.0 3.0 • 0.03-0.10

MM EC100H15R05CF-7T06 10.00 7 15.00 0.50 T06 9.60 22.00 36.0 3.0 • 0.04-0.10

MM EC120H18R05CF-7T08 12.00 7 18.00 0.50 T08 11.70 27.00 36.0 3.0 • 0.04-0.10

MM EC160H24R08CF-9T10 16.00 9 24.00 0.80 T10 15.30 33.50 36.0 1.0 • 0.05-0.10

MM EC200H30R10CF-9T12 20.00 9 30.00 1.00 T12 18.45 41.00 36.0 1.0 • 0.05-0.10

MM EC250H37R10CF-9T15 25.00 9 37.00 1.00 T15 23.90 52.50 36.0 1.0 • 0.05-0.10

• Do not apply lubricant to the threaded connection. (1) Number of flutes (2) Ramping angle maximum

RE APMX THSZMS Rd°

MM EC-CF-Z4-1.5xD

Interchangeable Solid Carbide Endmill DCONMS

Heads with 1.5xD Flute Lengths for DCe8

Chatter Free Roughing and Finishing

LF FHA

Recommended

Dimensions

Machining Data

IC908 fz

Designation DC NOF (1) APMX RE THSZMS DCONMS LF FHA (mm/t)

MM EC080H12R05CF-4T05 8.00 4 12.00 0.50 T05 7.70 18.00 46.5 • 0.03-0.09

MM EC100H15R05CF-4T06 10.00 4 15.00 0.50 T06 9.60 22.00 46.5 • 0.03-0.10

MM EC120H18R05CF-4T08 12.00 4 18.00 0.50 T08 11.70 27.00 46.5 • 0.04-0.11

MM EC160H24R05CF-4T10 16.00 4 24.00 0.50 T10 15.30 33.50 46.5 • 0.05-0.13

MM EC200H30R05CF-4T12 20.00 4 30.00 0.50 T12 18.45 41.00 46.5 • 0.05-0.17

MM EC250H37R05CF-4T15 25.00 4 37.00 0.50 T15 23.90 52.50 46.5 • 0.06-0.17

• Do not apply lubricant to the threaded connection. (1) Number of flutes

CHW APMX THSZMS

MM ERS-1.5xD

Interchangeable Solid Carbide Rough DCONMS Rd°

Milling Heads with 1.5xD Flute Lengths DCe9

for High Metal Removal Rates

LF FHA

Recommended

Dimensions

Machining Data

IC908 fz

Designation DC NOF (1) APMX CHW THSZMS DCONMS LF FHA RMPX (2) (mm/t)

MM ERS080B12-4T05 8.00 4 12.00 0.25 T05 7.70 18.00 46.0 90.0 • 0.03-0.08

MM ERS100B15-4T06 10.00 4 15.00 0.30 T06 9.60 22.00 46.0 90.0 • 0.03-0.09

MM ERS120B18-4T08 12.00 4 18.00 0.35 T08 11.70 27.00 46.0 90.0 • 0.04-0.10

MM ERS160B24-5T10 16.00 5 24.00 0.40 T10 15.30 33.50 40.0 7.0 • 0.04-0.10

MM ERS200B30-6T12 20.00 6 30.00 0.40 T12 18.45 41.00 47.0 3.0 • 0.05-0.11

MM ERS250B37-6T15 25.00 6 37.00 0.50 T15 23.90 52.50 47.0 3.0 • 0.05-0.11

• Do not apply lubricant to the threaded connection. (1) Number of flutes (2) Ramping angle maximum

DUSTRY 4.0

MACHINING IN TELLIGENTLY

92