Page 53 - logic

P. 53

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

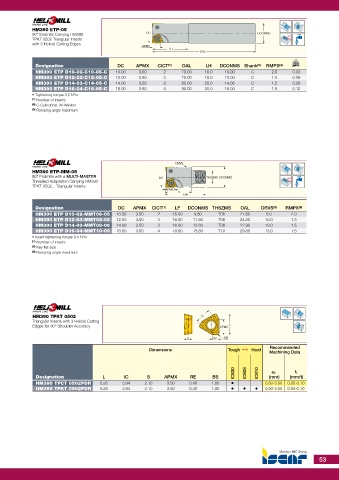

HM390 ETP-05

90° Endmills Carrying HM390 DC DCONMS Rd°

TPKT 0502 Triangular Inserts

with 3 Helical Cutting Edges

APMX

LH

OAL

Designation DC APMX CICT (1) OAL LH DCONMS Shank (2) RMPX (3) kg

HM390 ETP D10-02-C10-05-C 10.00 3.50 2 70.00 18.0 10.00 C 2.0 0.03

HM390 ETP D12-03-C12-05-C 12.00 3.50 3 70.00 18.0 12.00 C 1.5 0.06

HM390 ETP D14-03-C14-05-C 14.00 3.50 3 80.00 20.0 14.00 C 1.5 0.08

HM390 ETP D16-04-C16-05-C 16.00 3.50 4 90.00 20.0 16.00 C 1.5 0.12

• Tightening torque 0.5 N*m

(1) Number of inserts

(2) C-Cylindrical, W-Weldon

(3) Ramping angle maximum

DRVS

HM390 ETP-MM-05

90° Endmills with a MULTI-MASTER DC THSZMS DCONMS Rd°

Threaded Adaptation Carrying HM390

TPKT 0502... Triangular Inserts

APMX

LF

OAL

Designation DC APMX CICT (1) LF DCONMS THSZMS OAL DRVS (2) RMPX (3)

HM390 ETP D10-02-MMT06-05 10.00 3.50 2 15.00 9.60 T06 21.60 8.0 2.0

HM390 ETP D12-03-MMT08-05 12.00 3.50 3 16.00 11.60 T08 24.20 10.0 1.5

HM390 ETP D14-03-MMT08-05 14.00 3.50 3 16.00 13.60 T08 22.90 10.0 1.5

HM390 ETP D16-04-MMT10-05 16.00 3.50 4 18.00 15.60 T10 29.80 13.0 1.5

• Insert tightening torque 0.5 N*m

(1) Number of inserts

(2) Key flat size

(3) Ramping angle maximum

HM390 TPKT 0502 IC

Triangular Inserts with 3 Helical Cutting L

Edges for 90° Shoulder Accuracy APMX

S BS RE

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC808 IC810 ap fz

Designation L IC S APMX RE BS (mm) (mm/t)

HM390 TPCT 0502PDR 5.26 3.94 2.10 3.50 0.40 1.00 • 0.50-3.50 0.05-0.10

HM390 TPKT 0502PDR 5.26 3.94 2.10 3.50 0.40 1.00 • • • 0.50-3.50 0.05-0.10

53