Page 35 - logic

P. 35

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

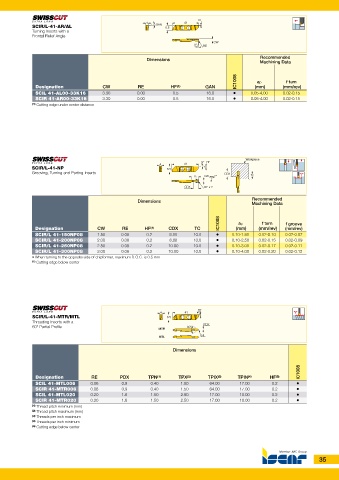

4 41 HF

SCIR/L-41-AR/AL GAN 8.5

Turning Inserts with a

Frontal Relief Angle

CW

8° RE

Recommended

Dimensions

Machining Data

IC1008 ap f turn

Designation CW RE HF (1) GAN (mm) (mm/rev)

SCIL 41-AL00-33K16 3.30 0.00 0.5 16.0 • 0.05-4.00 0.02-0.15

SCIR 41-AR00-33K16 3.30 0.00 0.5 16.0 • 0.05-4.00 0.02-0.15

(1) Cutting edge under center distance

4 41 9° HF Workpiece

SCIR/L-41-NP 8.5

Grooving, Turning and Parting Inserts CDX

Tc CW 7° Tc

CDX RE x 2

Recommended

Dimensions

Machining Data

IC1008 ap f turn f groove

Designation CW RE HF (1) CDX TC (mm) (mm/rev) (mm/rev)

SCIR/L 41-150NP08 1.50 0.08 0.2 8.00 10.0 • 0.10-1.80 0.02-0.10 0.02-0.07

SCIR/L 41-200NP08 2.00 0.08 0.2 8.00 10.0 • 0.10-2.50 0.02-0.15 0.02-0.09

SCIR/L 41-250NP08 2.50 0.08 0.2 10.00 10.0 • 0.10-3.00 0.02-0.17 0.02-0.11

SCIR/L 41-300NP08 3.00 0.08 0.2 10.00 10.0 • 0.10-4.00 0.02-0.20 0.02-0.12

• When turning to the opposite side of chipformer, maximum D.O.C. is 0.5 mm

(1) Cutting edge below center

4 41 HF

SCIR/L-41-MTR/MTL 8.5

Threading Inserts with a PDX

60° Partial Profile 60°

MTR

MTL RE

Dimensions

IC1008

Designation RE PDX TPN (1) TPX (2) TPIX (3) TPIN (4) HF (5)

SCIL 41-MTL006 0.06 0.9 0.40 1.50 64.00 17.00 0.2 •

SCIR 41-MTR006 0.06 0.9 0.40 1.50 64.00 17.00 0.2 •

SCIL 41-MTL020 0.20 1.6 1.50 2.50 17.00 10.00 0.2 •

SCIR 41-MTR020 0.20 1.6 1.50 2.50 17.00 10.00 0.2 •

(1) Thread pitch minimum (mm)

(2) Thread pitch maximum (mm)

(3) Threads per inch maximum

(4) Threads per inch minimum

(5) Cutting edge below center

35