Page 823 - Iscar

P. 823

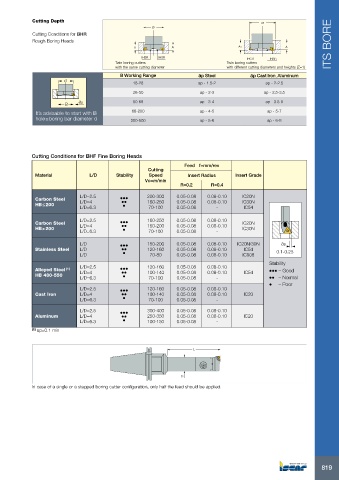

Cutting Depth

Ø

Ø

Cutting Conditions for BHR

Rough Boring Heads

A A A1 A ITS BORE

IHSR

IHSR IHSR

IHCR IHSR

Twin boring cutters Twin boring cutters

with the same cutting diameter with different cutting diameters and heights (Z=1)

B Working Range ap Steel ap Cast Iron, Aluminum

d

18-28 ap - 1.5-2 ap - 2-2.5

28-50 ap - 2-3 ap - 2.5-3.5

B ap 50-68 ap - 3-4 ap - 3.5-5

It’s advisable to start with B 68-200 ap - 4-5 ap - 5-7

hole≥boring bar diameter d 200-500 ap - 5-6 ap - 6-8

Cutting Conditions for BHF Fine Boring Heads

Feed f=mm/rev

Cutting

Material L/D Stability Speed Insert Radius Insert Grade

Vc=m/min

R=0.2 R=0.4

L/D=2.5 200-300 0.05-0.08 0.08-0.10 IC20N

Carbon Steel L/D=4 ●●● 160-250 0.05-0.08 0.08-0.10 IC30N

HB≤200 ●●

●

L/D=6.3 70-100 0.05-0.08 - IC54

L/D=2.5 160-250 0.05-0.08 0.08-0.10

Carbon Steel L/D=4 ●●● 150-200 0.05-0.08 0.08-0.10 IC20N

HB>200 ●● IC30N

●

L/D=6.3 70-100 0.05-0.08 -

L/D ●●● 150-200 0.05-0.08 0.08-0.10 IC20N/30N ap

Stainless Steel L/D ●● 120-160 0.05-0.08 0.08-0.10 IC54 0.1-0.25

L/D ● 70-80 0.05-0.08 0.08-0.10 IC908

Stability

L/D=2.5 120-160 0.05-0.08 0.08-0.10

Alloyed Steel (1) L/D=4 ●●● 100-140 0.05-0.08 0.08-0.10 IC54 ●●●

– Good

HB 480-550 ●●

●

L/D=6.3 70-100 0.05-0.08 - ●● – Normal

● – Poor

L/D=2.5 ●●● 120-160 0.05-0.08 0.08-0.10

Cast Iron L/D=4 ●● 100-140 0.05-0.08 0.08-0.10 IC20

L/D=6.3 ● 70-100 0.05-0.08 -

L/D=2.5 ●●● 300-400 0.05-0.08 0.08-0.10

Aluminum L/D=4 ●● 250-350 0.05-0.08 0.08-0.10 IC20

L/D=6.3 ● 100-150 0.05-0.08 -

(1) ap=0.1 min

L

.0015 0 .0005 .001

D

In case of a single or a stepped boring cutter configuration, only half the feed should be applied.

819