Page 712 - Iscar

P. 712

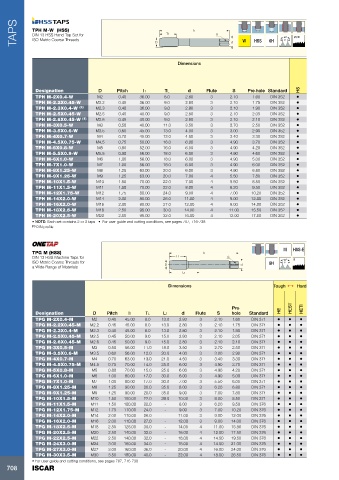

TAPS TPH M-W (HSS) D TL l1 S d W HSS 6H 60˚ P I/II/III

DIN 13 HSS Hand Tap Set for

ISO Metric Coarse Threads

Dimensions

Designation D Pitch l1 TL d Flute S Pre-hole Standard HS

TPH M-2X0.4-W M2 0.40 36.00 8.0 2.80 3 2.10 1.60 DIN 352 •

TPH M-2.2X0.45-W M2.2 0.45 36.00 9.0 2.80 3 2.10 1.75 DIN 352 •

TPH M-2.3X0.4-W (1) M2.3 0.40 36.00 9.0 2.80 3 2.10 1.90 DIN 352 •

TPH M-2.5X0.45-W M2.5 0.45 40.00 9.0 2.80 3 2.10 2.05 DIN 352 •

TPH M-2.6X0.45-W (1) M2.6 0.45 40.00 9.0 2.80 3 2.10 2.10 DIN 352 •

TPH M-3X0.5-W M3 0.50 40.00 11.0 3.50 3 2.70 2.50 DIN 352 •

TPH M-3.5X0.6-W M3.5 0.60 45.00 13.0 4.00 3 3.00 2.90 DIN 352 •

TPH M-4X0.7-W M4 0.70 45.00 13.0 4.50 3 3.40 3.30 DIN 352 •

TPH M-4.5X0.75-W M4.5 0.75 50.00 16.0 6.00 3 4.90 3.70 DIN 352 •

TPH M-5X0.8-W M5 0.80 52.00 16.0 6.00 3 4.90 4.20 DIN 352 •

TPH M-5.5X0.9-W M5.5 0.90 56.00 18.0 6.00 3 4.90 4.60 DIN 352 •

TPH M-6X1.0-W M6 1.00 56.00 18.0 6.00 3 4.90 5.00 DIN 352 •

TPH M-7X1.0-W M7 1.00 56.00 18.0 6.00 3 4.90 6.00 DIN 352 •

TPH M-8X1.25-W M8 1.25 63.00 20.0 6.00 3 4.90 6.80 DIN 352 •

TPH M-9X1.25-W M9 1.25 63.00 20.0 7.00 4 5.50 7.80 DIN 352 •

TPH M-10X1.5-W M10 1.50 70.00 22.0 7.00 4 5.50 8.50 DIN 352 •

TPH M-11X1.5-W M11 1.50 70.00 22.0 8.00 4 6.20 9.50 DIN 352 •

TPH M-12X1.75-W M12 1.75 80.00 24.0 9.00 4 7.00 10.20 DIN 352 •

TPH M-14X2.0-W M14 2.00 80.00 26.0 11.00 4 9.00 12.00 DIN 352 •

TPH M-16X2.0-W M16 2.00 80.00 27.0 12.00 4 9.00 14.00 DIN 352 •

TPH M-18X2.5-W M18 2.50 95.00 30.0 14.00 4 11.00 15.50 DIN 352 •

TPH M-20X2.5-W M20 2.50 95.00 32.0 16.00 4 12.00 17.50 DIN 352 •

• NOTE: Each set contains 2 or 3 taps • For user guide and cutting conditions, see pages 707, 716-738

(1) DIN profile

TPG M (HSS) l1 M HSS-E

DIN 13 HSS Machine Taps for TL S 60˚ B

ISO Metric Coarse Threads for D d 6H P

a Wide Range of Materials

L1

Dimensions Tough 1 Hard

Pre- HEST HETI

Designation D Pitch l1 TL L1 d Flute S hole Standard HE

TPG M-2X0.4-M M2 0.40 45.00 8.0 13.0 2.80 3 2.10 1.60 DIN 371 • • •

TPG M-2.2X0.45-M M2.2 0.45 45.00 8.0 13.0 2.80 3 2.10 1.75 DIN 371 • • •

TPG M-2.3X0.4-M M2.3 0.40 45.00 8.0 13.0 2.80 3 2.10 1.90 DIN 371 • • •

TPG M-2.5X0.45-M M2.5 0.45 50.00 9.0 15.0 2.80 3 2.10 2.05 DIN 371 • • •

TPG M-2.6X0.45-M M2.6 0.45 50.00 9.0 15.0 2.80 3 2.10 2.10 DIN 371 • • •

TPG M-3X0.5-M M3 0.50 56.00 11.0 18.0 3.50 3 2.70 2.50 DIN 371 • • •

TPG M-3.5X0.6-M M3.5 0.60 56.00 12.0 20.0 4.00 3 3.00 2.90 DIN 371 • • •

TPG M-4X0.7-M M4 0.70 63.00 13.0 21.0 4.50 3 3.40 3.30 DIN 371 • • •

TPG M-4.5X0.75-M M4.5 0.75 70.00 14.0 25.0 6.00 3 4.90 3.70 DIN 371 • • •

TPG M-5X0.8-M M5 0.80 70.00 15.0 25.0 6.00 3 4.90 4.20 DIN 371 • • •

TPG M-6X1.0-M M6 1.00 80.00 17.0 30.0 6.00 3 4.90 5.00 DIN 371 • • •

TPG M-7X1.0-M M7 1.00 80.00 17.0 30.0 7.00 3 5.50 6.00 DIN 371 • • •

TPG M-8X1.25-M M8 1.25 90.00 20.0 35.0 8.00 3 6.20 6.80 DIN 371 • • •

TPG M-9X1.25-M M9 1.25 90.00 20.0 35.0 9.00 3 7.00 7.80 DIN 371 • • •

TPG M-10X1.5-M M10 1.50 100.00 22.0 39.0 10.00 3 8.00 8.50 DIN 371 • • •

TPG M-11X1.5-M M11 1.50 100.00 22.0 - 8.00 3 6.20 9.50 DIN 376 • • •

TPG M-12X1.75-M M12 1.75 110.00 24.0 - 9.00 3 7.00 10.20 DIN 376 • • •

TPG M-14X2.0-M M14 2.00 110.00 26.0 - 11.00 3 9.00 12.00 DIN 376 • • •

TPG M-16X2.0-M M16 2.00 110.00 27.0 - 12.00 3 9.00 14.00 DIN 376 • • •

TPG M-18X2.5-M M18 2.50 125.00 30.0 - 14.00 4 11.00 15.50 DIN 376 • • •

TPG M-20X2.5-M M20 2.50 140.00 32.0 - 16.00 4 12.00 17.50 DIN 376 • • •

TPG M-22X2.5-M M22 2.50 140.00 32.0 - 18.00 4 14.50 19.50 DIN 376 • • •

TPG M-24X3.0-M M24 3.00 160.00 34.0 - 18.00 4 14.50 21.00 DIN 376 • • •

TPG M-27X3.0-M M27 3.00 160.00 36.0 - 20.00 4 16.00 24.00 DIN 376 • • •

TPG M-30X3.5-M M30 3.50 180.00 40.0 - 22.00 4 18.00 26.50 DIN 376 • • •

• For user guide and cutting conditions, see pages 707, 716-738

708 ISCAR