Page 236 - Iscar

P. 236

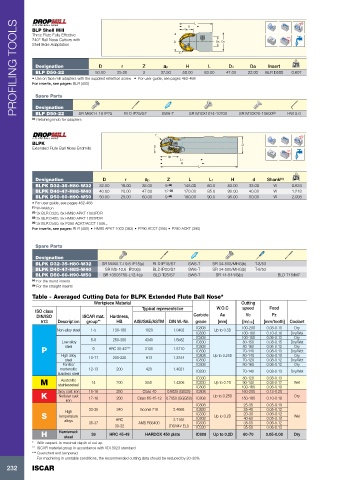

PROFILING TOOLS BLP Shell Mill 50.00 25.00 Z 37.50 D r 50.00 L 83.00 Da D3 47.00 22.00 BLR D500 Rd° 0.607

H

ap

Three Flute Fully Effective

240° Ball Nose Cutters with

Shell Hole Adaptation

kg

Da

r

D

H

L

Designation

Insert

D3

ap

BLP D50-22

3

• Use on face mill adapters with the supplied retention screw • For user guide, see pages 462-468

For inserts, see pages: BLR (455)

Spare Parts

Designation

BLP D50-22

SR M6X1-L18 IP25

(a) Retaining knob for adapters BLD IP25/S7 SW6-T SR M10X1X14-10700 SR M10X20-10600 (a) HW 5.0

r

BLPK d

Extended Flute Ball Nose Endmills D

Rd°

ap

L1

H

L

Designation D r ap Z L L1 H d Shank (1) kg

BLPK D32-35-H80-W32 32.00 16.00 35.00 9 (2) 145.00 80.0 83.00 32.00 W 0.634

BLPK D40-47-H85-W40 40.00 20.00 47.00 12 (3) 170.00 85.0 90.00 40.00 W 1.218

BLPK D50-60-H90-W50 50.00 25.00 60.00 9 (4) 180.00 90.0 95.00 50.00 W 2.008

• For user guide, see pages 462-468

(1) W-Weldon

(2) 3x BLR D320, 6x HM90 APKT 1003PDR

(3) 3x BLR D400, 9x HM90 APKT 1003PDR

(4) 3x BLR D500, 6x P290 ACKT/ACCT 1806...

For inserts, see pages: BLR (455) • HM90 APKT 1003 (383) • P290 ACCT (395) • P290 ACKT (395)

Spare Parts

Designation

BLPK D32-35-H80-W32 SR M4X0.7-L9.6 IP15(a) BLD IP15/S7 SW6-T SR 34-505/MHG(b) T-8/53

BLPK D40-47-H85-W40 SR M5-10.6 IP20(a) BLD IP20/S7 SW6-T SR 34-505/MHG(b) T-8/53

BLPK D50-60-H90-W50 SR 10503750-L12.4(a) BLD T25/S7 SW6-T SR 14-544/S(b) BLD T15/M7

(a) For the round inserts

(b) For the straight inserts

Table - Averaged Cutting Data for BLPK Extended Flute Ball Nose*

Workpiece Material Cutting

Typical representstive W.O.C speed Feed

ISO class

DIN/ISO ISCAR mat. Hardness, Carbide Ae Vc Fz

513 Description group** HB AISI/SAE/ASTM DIN W.-Nr. grade [mm] [m/min] [mm/tooth] Coolant

IC808 100-200 0.08-0.15 Dry

Non-alloy steel 1-5 130-180 1020 1.0402 Up to 0.3D

IC830 100-180 0.10-0.16 Dry/Wet

6-8 260-300 4340 1.6582 IC808 100-180 0.06-0.13 Dry

Low alloy IC830 80-150 0.08-0.15 Dry/Wet

Dry

P steel 9 HRC 35-42*** 3135 1.5710 IC808 80-160 0.06-0.12 Dry/Wet

0.08-0.13

IC830

70-140

High alloy 10-11 200-220 H13 1.2344 IC808 Up to 0.25D 80-140 0.06-0.10 Dry

steel IC830 70-120 0.08-0.12 Dry/Wet

Ferritic/ IC808 80-160 0.06-0.12 Dry

martensitic 12-13 200 420 1.4021

stainless steel IC830 70-140 0.08-0.13 Dry/Wet

M Austenitic 14 200 304L 1.4306 IC330 Up to 0.2D 80-120 0.08-0.13 Wet

IC830

90-140

0.08-0.12

stainlesssteel

IC808 100-160 0.06-0.10

Grey cast iron 15-16 250 Class 40 0.6025 (GG25) IC808 160-200 0.12-0.20

K Nodular cast Up to 0.25D Dry

iron 17-18 200 Class 65-45-12 0.7050 (GGG50) IC808 150-180 0.10-0.18

IC808 25-35 0.05-0.10

High 33-35 340 Inconel 718 2.4668 IC830 25-40 0.05-0.12

S temperature IC330 Up to 0.2D 20-30 0.06-0.12 Wet

alloys HRC 3.7165 IC808 40-60 0.05-0.10

36-37 AMS R56400 IC830 35-55 0.06-0.12

30-32 (Ti6Al4V ELI) IC330 35-50 0.06-0.13

H Hardened- 38 HRC 45-49 HARDOX 450 plate IC808 Up to 0.2D 60-70 0.05-0.08 Dry

steel

* With respect to maximal depth of cut ap

** ISCAR material group in accordance with VDI 3323 standard

*** Quenched and tempered

For machining in unstable conditions, the recommended cutting data should be reduced by 20-30%

232 ISCAR