Page 1006 - Iscar

P. 1006

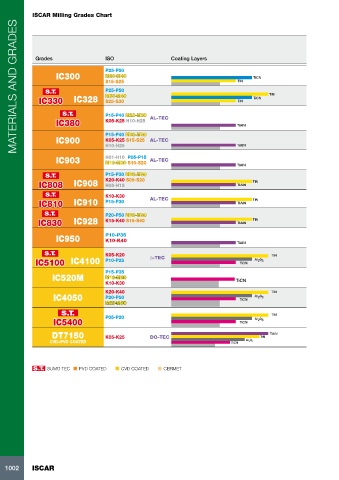

ISCAR Milling Grades Chart

MATERIALS AND GRADES

Grades ISO Coating Layers Recommended Applications

P25-P50

IC300 M20-M40 TiCN A tough submicron TiN/TiCN PVD coated grade. Suitable for milling heat resistant alloys, austenitic

stainless steel and carbon steel at unfavorable conditions, at low to medium cutting speeds.

S15-S25 TiN

S.T. P25-P50 TiN A TiN/TiCN PVD coated tough grade. Used for milling, grooving, parting and drilling a

IC330 IC328 M30-M40 TiN TiCN wide range of workpiece materials, at low to medium cutting speeds.

S25-S30

A tough submicron substrate, TiCN PVD coated and a special surface treatment. Designed for

S.T. P15-P40 M20-M30 machining titanium and heat resistant alloys, austenitic stainless steel, at medium to high cutting speeds,

IC380 K05-K25 H10-H25 AL-TEC TiAIN interrupted cut and unfavorable conditions. Excellent notch wear and built-up edge resistance. High

resistance to mechanical and thermal shock – therefore milling with coolant may be applied.

P15-P40 M20-M30 A tough, submicron PVD TiAlN coated grade. Suitable for milling heat resistant alloys, austenitic

IC900 K05-K25 S15-S25 AL-TEC

H10-H25 TiAIN stainless steel, hard alloys and carbon steel at medium to high cutting speeds.

IC903 H01-H10 P05-P15 AL-TEC Ultra-fine grain carbide with 12% cobalt, TiAlN PVD coated grade. Used for up to 62 HRc hardened steel, titanium,

M10-M20 S10-S20

nickel-based alloys and stainless steel at high speeds and medium feeds. A tough and highly wear resistant grade.

TiAIN

S.T. P15-P30 M20-M30 A tough submicron substrate, TiAlN PVD coated grade. Designed for machining heat resistant alloys,

IC808 IC908 K20-K40 S05-S20 TIAIN TiN austenitic stainless steel, hard alloys and carbon steel at medium to high cutting speeds, interrupted

H05-H15

cut and unfavorable conditions. Excellent notch wear and built-up edge resistance.

S.T. K10-K30 AL-TEC A PVD TiAlN coated grade. First choice for milling nodular cast iron at medium to high cutting speeds.

IC810 IC910 P15-P30 TIAIN TiN

S.T. P20-P50 M20-M30 A PVD TiAlN coated tough grade. Suitable for milling stainless steel, high temperature alloys and other alloy steels.

IC830 IC928 K15-K40 S15-S40 TIAIN TiN Recommended for interrupted cut and heavy operations.

IC950 P10-P35 A PVD TiAlN coated grade. Used for heavy milling alloy steel and cast iron. Features excellent wear resistance.

K10-K40

TiAIN

S.T. K05-K20 TiN A tough substrate with a new MTCVD and TiCN/Al2O3 coating. Recommended for

IC5100 IC4100 P10-P25 a-TEC TiCN Al 2 0 3 milling grey cast iron at high cutting speeds, providing extended tool life.

P15-P35 A TiCN CVD coated grade. Used for milling and drilling steel, malleable cast iron and

IC520M M10-M20 stainless steel at medium feeds and medium to high cutting speeds.

K10-K30 TiCN

K20-K40 TiN A TiCN/TiC/Al2O3 multilayer, CVD coated grade. Used for milling grey and nodular cast

IC4050 P20-P50 TiCN Al 2 0 3 iron, at medium to high cutting speeds. A high wear resistant grade.

M20-M30

S.T. TiN A tough substrate with a new MTCVD and alpha Al2O3 coating. Recommended for milling steel at high cutting speed providing

IC5400 P05-P20 TiCN Al 2 0 3 excellent tool life.

DT7150 K05-K25 DO-TEC TiN TiAIN A tough substrate with a dual MTCVD Al2O3 and TiAlN PVD coating. Recommended for medium to high cutting

CVD+PVD COATED TiCN Al 2 0 3 speeds for machining of both grey and nodular cast iron. Features high wear and chipping resistance.

S.T. SUMO TEC PVD COATED CVD COATED CERMET

1002 ISCAR