Page 94 - CAMFIX

P. 94

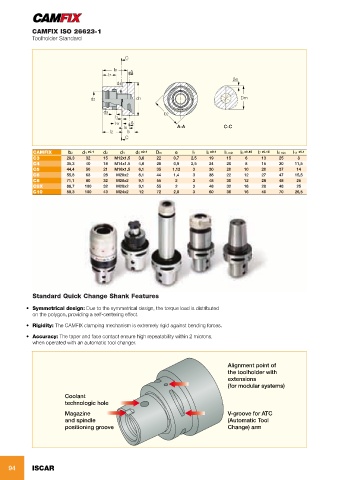

CAMFIX ISO 26623-1

Toolholder Standard

C

l8 A

l7

2e

d4

d2 d1 Dm

d5 b2

l1

l11 A

l6 A-A C-C

l2 l3

C

CAMFIX b2 d1 ±0.1 d2 d4 d5 ±0.1 Dm e l1 l2 ±0.1 l3 min l6 ±0.15 l7 ±0.15 l8 min l11 ±0.1

C3 28,3 32 15 M12x1.5 3,6 22 0,7 2,5 19 15 6 13 25 8

C4 35,3 40 18 M14x1.5 4,6 28 0,9 2,5 24 20 8 15 30 11,5

C5 44,4 50 21 M16x1.5 6,1 35 1,12 3 30 20 10 20 37 14

C6 55,8 63 28 M20x2 8,1 44 1,4 3 38 22 12 27 47 15,5

C8 71,1 80 32 M20x2 9,1 55 2 3 48 30 12 28 48 25

C8X 88,7 100 32 M20x2 9,1 55 2 3 48 32 16 28 48 25

C10 88,3 100 43 M24x2 12 72 2,8 3 60 36 16 40 70 26,5

Standard Quick Change Shank Features

• Symmetrical design: Due to the symmetrical design, the torque load is distributed

on the polygon, providing a self-centering effect.

• Rigidity: The CAMFIX clamping mechanism is extremely rigid against bending forces.

• Accuracy: The taper and face contact ensure high repeatability within 2 microns,

when operated with an automatic tool changer.

Alignment point of

the toolholder with

extensions

(for modular systems)

Coolant

technologic hole

Magazine V-groove for ATC

and spindle (Automatic Tool

positioning groove Change) arm

94 ISCAR