Page 87 - CAMFIX

P. 87

Quick Change

CGHN-S MACHINING PERFORMANCE

High Precision

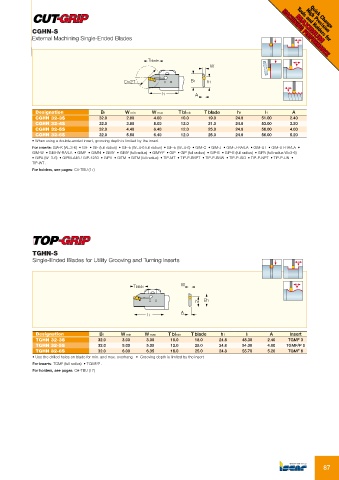

External Machining Single-Ended Blades

Tools and Holders for

MAXIMUM

Tblade

W

D=2T B1 h1

l1 A

Designation B1 W min W max T blmin T blade h1 l1 A

CGHN 32-3S 32.0 2.80 4.00 10.0 19.0 24.8 51.00 2.40

CGHN 32-4S 32.0 3.50 5.00 12.0 21.0 24.8 53.00 3.20

CGHN 32-5S 32.0 4.40 6.40 12.0 25.0 24.8 56.00 4.00

CGHN 32-6S 32.0 5.50 6.40 12.0 25.0 24.8 56.00 5.20

• When using a double-ended insert, grooving depth is limited by the insert.

For inserts: GIA-K (W=3-6) • GIF • GIF (full radius) • GIF-E (W=4-6 full radius) • GIF-E (W=4-6) • GIM-C • GIM-J • GIM-J-RA/LA • GIM-UT • GIM-UT-RA/LA •

GIM-W • GIM-W-RA/LA • GIMF • GIMN • GIMY • GIMY (full radius) • GIMY-F • GIP • GIP (full radius) • GIP-E • GIP-E (full radius) • GIPA (full radius W=3-6)

• GIPA (W=3-6) • GIPM-A46 / GIP-1250 • GIPY • GITM • GITM (full radius) • TIP-MT • TIP-P-BSPT • TIP-P-BSW • TIP-P-ISO • TIP-P-NPT • TIP-P-UN •

TIP-WT .

For holders, see pages: C#-TBU (17)

TGHN-S

Single-Ended Blades for Utility Grooving and Turning Inserts

W

Tblade

h1 B1

A

l1

Designation B1 W min W max T blmin T blade h1 l1 A Insert

TGHN 32-3S 32.0 3.00 3.00 10.0 18.0 24.8 48.30 2.40 TGMF 3

TGHN 32-5S 32.0 5.00 5.00 12.0 25.0 24.8 54.00 4.00 TGMF/P 5

TGHN 32-6S 32.0 6.00 6.35 16.0 25.0 24.8 55.70 5.20 TGMF 6

• Use the drilled holes on blade for min. and max. overhang • Grooving depth is limited by the insert

For inserts: TGMF (full radius) • TGMF/P .

For holders, see pages: C#-TBU (17)

87