Page 80 - CAMFIX

P. 80

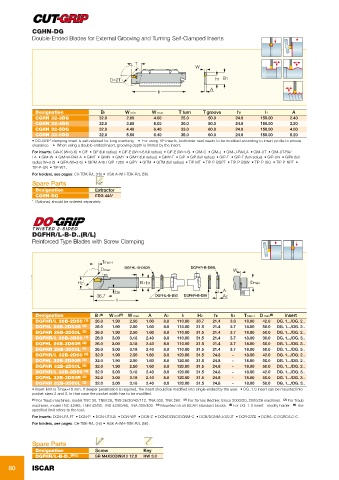

CGHN-DG

Double-Ended Blades for External Grooving and Turning Self-Clamped Inserts

T

W

D=2T h1 B1

A

l1

Designation B1 W min W max T turn T groove h1 l1 A

CGHN 32-3DG 32.0 2.80 4.00 25.0 50.0 24.8 150.00 2.40

CGHN 32-4DG 32.0 3.50 5.00 30.0 50.0 24.8 150.00 3.20

CGHN 32-5DG 32.0 4.40 6.40 33.0 60.0 24.8 150.00 4.00

CGHN 32-6DG 32.0 5.50 6.40 35.0 60.0 24.8 150.00 5.20

• DO-GRIP clamping insert is self-retained for long overhang. • For using TIP inserts, toolholder seat needs to be modified according to insert profile to ensure

clearance. • When using a double-ended insert, grooving depth is limited by the insert.

For inserts: GIA-K (W=3-6) • GIF • GIF (full radius) • GIF-E (W=4-6 full radius) • GIF-E (W=4-6) • GIM-C • GIM-J • GIM-J-RA/LA • GIM-UT • GIM-UT-RA/

LA • GIM-W • GIM-W-RA/LA • GIMF • GIMN • GIMY • GIMY (full radius) • GIMY-F • GIP • GIP (full radius) • GIP-E • GIP-E (full radius) • GIP-UN • GIPA (full

radius W=3-6) • GIPA (W=3-6) • GIPM-A46 / GIP-1250 • GIPY • GITM • GITM (full radius) • TIP-MT • TIP-P-BSPT • TIP-P-BSW • TIP-P-ISO • TIP-P-NPT •

TIP-P-UN • TIP-WT .

For holders, see pages: C#-TBK-R/L (16) • HSK A-WH-TBK-R/L (56)

Spare Parts

Designation Extractor

CGHN-DG EDG 44A*

* Optional, should be ordered separately

DGFHR/L-B-D..(R/L)

Reinforced Type Blades with Screw Clamping

Tmax-r

DGFHL-B-D50R DGFHR-B-D50L

Dmax W

H2 B1 h1 Dmax

A

h4

36.7 DGFHL-B-D50 DGFHR-B-D50 A2

l1

Designation B1 (4) W min (5) W max A A2 l1 H2 h1 h4 Tmax-r D max (6) Insert

DGFHR/L 26B-2D50 (1) 26.0 1.90 2.50 1.60 8.0 110.00 33.7 21.4 3.6 18.00 42.0 DG. 1.../DG. 2..

DGFHL 26B-2D50R (2) 26.0 1.90 2.50 1.60 8.0 110.00 31.5 21.4 3.7 18.00 50.0 DG. 1.../DG. 2..

DGFHR 26B-2D50L (2) 26.0 1.90 2.50 1.60 8.0 110.00 31.5 21.4 3.7 18.00 50.0 DG. 1.../DG. 2..

DGFHR/L 26B-3D50 (1) 26.0 3.00 3.18 2.40 8.0 110.00 31.5 21.4 3.7 18.00 30.0 DG. 1.../DG. 3..

DGFHL 26B-3D50R (2) 26.0 3.00 3.18 2.40 8.0 110.00 31.5 21.4 3.7 18.00 50.0 DG. 1.../DG. 3..

DGFHR 26B-3D50L (2) 26.0 3.00 3.18 2.40 8.0 110.00 31.5 21.4 3.7 18.00 50.0 DG. 1.../DG. 3..

DGFHR/L 32B-2D50 (3) 32.0 1.90 2.50 1.60 8.0 120.00 31.5 24.8 - 18.00 42.0 DG. 1.../DG. 2..

DGFHL 32B-2D50R (2) 32.0 1.90 2.50 1.60 8.0 120.00 31.5 24.8 - 18.00 50.0 DG. 1.../DG. 2..

DGFHR 32B-2D50L (2) 32.0 1.90 2.50 1.60 8.0 120.00 31.5 24.8 - 18.00 50.0 DG. 1.../DG. 2..

DGFHR/L 32B-3D50 (3) 32.0 3.00 3.18 2.40 8.0 120.00 31.5 24.8 - 18.00 42.0 DG. 1.../DG. 3..

DGFHL 32B-3D50R (2) 32.0 3.00 3.18 2.40 8.0 120.00 31.5 24.8 - 18.00 50.0 DG. 1.../DG. 3..

DGFHR 32B-3D50L (2) 32.0 3.00 3.18 2.40 8.0 120.00 31.5 24.8 - 18.00 50.0 DG. 1.../DG. 3..

• Insert limit is Tmax=18 mm. If deeper penetration is required, the insert should be modified into single-ended by the user. • DG..1.0 insert can be mounted into

pocket sizes 2 and 3. In that case the pocket width has to be modified.

(1) For Traub machines, model TNC 30, TNM 28, TNS 26/30/42/112, TNA 300, TNK 260. (2) For Tornos Bechler, Emco 2000/20, 2000/26 machines. (3) For Traub

machines, model TNC 42/65, TNM 42/65, TNS 42/60/65, TNA 300/400. (4) Mounted on all ISCAR standard blocks. (5) For DG: 1.0 insert - modify holder. (6) The

specified limit refers to the tool.

For inserts: DGN-LF/LFT • DGN-P • DGN-UT/UA • DGN-WP • DGN-Z • DGN/DGNC/DGNM-C • DGN/DGNM-J/JS/JT • DGR-Z/ZS • DGR/L-C DGRC/LC-C .

For holders, see pages: C#-TBK-R/L (16) • HSK A-WH-TBK-R/L (56) .

Spare Parts

Designation Screw Key

DGFHR/L-B-D.. (R/L) SR M4X20DIN912 12.9 HW 3.0

80 ISCAR