Page 39 - 2017-Tooling-System

P. 39

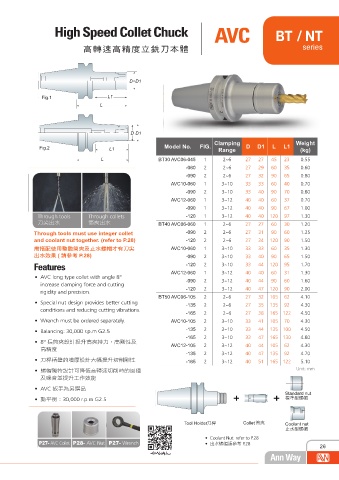

High Speed Collet Chuck AVC BT / NT

高轉速高精度立銑刀本體 series

D=D1

Fig.1 L1

L

D D1

Clamping Weight

Fig.2 L1 Model No. FIG. Range D D1 L L1 (kg)

L BT30 AVC06-045 1 2~6 27 27 45 23 0.55

-060 2 2~6 27 29 60 35 0.60

-090 2 2~6 27 32 90 65 0.80

AVC10-060 1 3~10 33 33 60 40 0.70

-090 2 3~10 33 40 90 70 0.80

AVC12-060 1 3~12 40 40 60 37 0.70

-090 1 3~12 40 40 90 67 1.00

Through tools Through collets -120 1 3~12 40 40 120 97 1.30

刀尖出水 筒夾出水 BT40 AVC06-060 1 2~6 27 27 60 30 1.20

Through tools must use integer collet -090 2 2~6 27 31 90 60 1.35

and coolant nut together. (refer to P.28) -120 2 2~6 27 34 120 90 1.50

需搭配使用整數筒夾及止水螺帽才有刀尖 AVC10-060 1 3~10 33 33 60 35 1.30

出水效果 ( 請參考 P.28) -090 2 3~10 33 40 90 65 1.50

Features -120 2 3~10 33 44 120 95 1.70

AVC12-060 1 3~12 40 40 60 31 1.30

• AVC long type collet with angle 8° -090 2 3~12 40 44 90 60 1.60

increase clamping force and cutting

-120 2 3~12 40 47 120 90 2.00

rigidity and precision.

BT50 AVC06-105 2 2~6 27 32 105 62 4.10

• Special nut design provides better cutting -135 2 2~6 27 35 135 92 4.30

conditions and reducing cutting vibrations.

-165 2 2~6 27 38 165 122 4.50

• Wrench must be ordered separately. AVC10-105 2 3~10 33 41 105 70 4.30

• Balancing: 30,000 r.p.m G2.5 -135 2 3~10 33 44 135 100 4.50

-165 2 3~10 33 47 165 130 4.80

• 8° 長筒夾設計提升高夾持力,高剛性及 AVC12-105 2 3~12 40 44 105 62 4.30

高精度

-135 2 3~12 40 47 135 92 4.70

• 刀桿柄壁的增厚設計大幅提升切削剛性 -165 2 3~12 40 51 165 122 5.10

• 螺帽獨特設計可降低高轉速切削時的風阻 Unit: mm

及噪音並提升工作效能

• AVC 扳手為另購品

Standard nut

• 動平衡:30,000 r.p.m G2.5 標準型螺帽

Tool Holder 刀桿 Collet 筒夾 Coolant nut

止水型螺帽

• Coolant Nut: refer to P.28

P27- AVC Collet P28- AVC Nut P27- Wrench • 出水螺帽請參考 P.28

26

Ann Way